SAE 45 degree flare fittings provide versatile and reliable connections for fluid systems. Their ability to create secure, leak-free seals, resistance to vibration and pressure, ease of installation and maintenance, and compatibility with various piping materials make them a popular choice in multiple industries. Whether in hydraulic systems, fuel lines, or other fluid applications, SAE 45 degree flare fittings ensure efficient and safe fluid transfer while maintaining system integrity.

Overview of SAE 45 Degree Flare Fittings:SAE 45 degree flare fittings are designed with a specific flare angle of 45 degrees, which ensures a tight and reliable connection. They consist of a fitting body with a flared end and a nut that compresses the flare onto the mating surface. The fittings are typically made of brass, steel, or stainless steel, offering durability and resistance to corrosion.

Secure and Leak-Free Connections:One of the primary advantages of SAE 45 degree flare fittings is their ability to create secure and leak-free connections. The flare design, along with the compression provided by the nut, forms a tight seal between the fitting and the mating surface. This sealing mechanism prevents fluid leakage, even under high-pressure conditions. The reliable connection ensures the efficiency and safety of fluid systems.

Vibration and Pressure Resistance:SAE 45 degree flare fittings are known for their excellent resistance to vibration and pressure. The flared connection, when properly assembled, offers enhanced resistance to loosening or disconnection due to mechanical vibrations or fluctuations in system pressure. This feature is particularly beneficial in applications where vibrations or pressure variations are common, such as automotive, hydraulic, and pneumatic systems.

Ease of Installation and Maintenance: SAE 45 degree flare fittings from sae 45 degree flare fittings manufacturers are relatively easy to install and maintain.The flared end of the fitting allows for simple insertion into the mating component. The nut is then tightened to secure the connection, ensuring a reliable seal. Additionally, disassembly and reassembly of the fittings are straightforward, facilitating maintenance or system modifications without the need for specialized tools.

Versatile Applications:SAE 45 degree flare fittings find extensive use in a variety of industries and applications. They are commonly employed in hydraulic systems, fuel lines, air conditioning systems, refrigeration systems, and gas distribution networks. The fittings are compatible with various types of pipes or tubing, including copper, steel, and aluminum, offering versatility in system design and configuration.

Wide Availability and Compatibility:SAE 45 degree flare fittings are widely available and compatible with other flare fittings that conform to SAE standards. This compatibility allows for interchangeability and easy replacement options. Additionally, a range of sizes and configurations are offered to accommodate different system requirements, ensuring flexibility in design and installation.

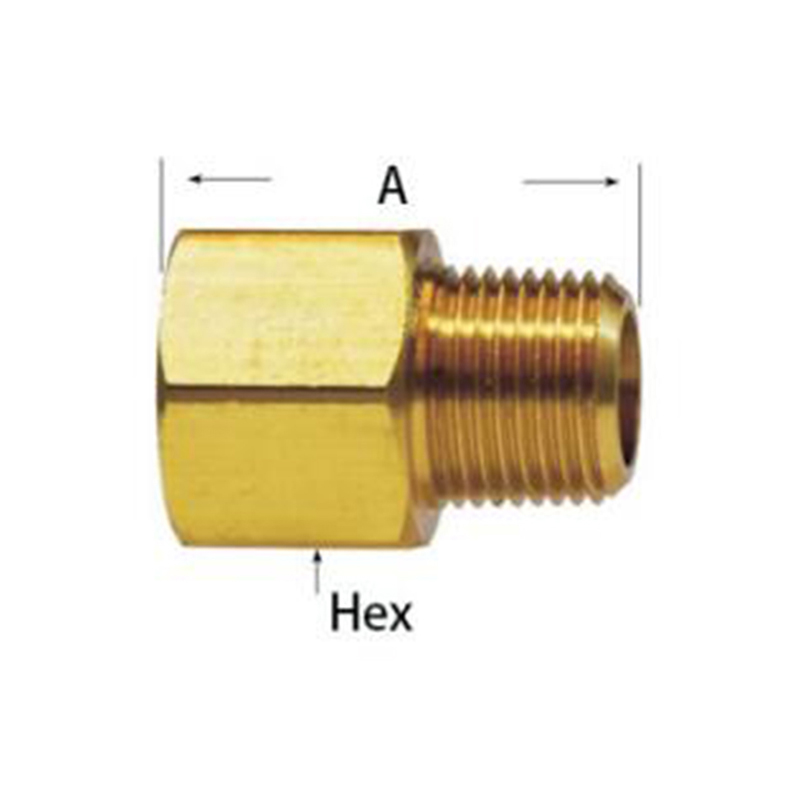

Female Flare Adapter

Xiangjia Machinery has passed the IATF 16949:2016 system certification, and is a professional manufacturer of brass fittings, AIR BRAKE HOSE ASSEMBLIES, stainless steel fittings, ISO 9001 & ISO 14001 system certification, DOT, AMECA product certification.

English

English 中文简体

中文简体